ZLC-0513中性清洗剂中蓝清洗

LPC-0513环保、中性清洗剂

本品针对各类石油、化工装置及工业机加工时在生产过程中生成的水垢和锈垢,具有优良的清洗效果,使用安全可靠;比传统的清洗更安全、环保、经济和实用。

对碳钢、不锈钢、黄铜、紫铜和铝等材质的腐蚀率<0.3g/㎡·h以下, 对以上材质器件清洗过程中腐蚀远远低于HG/T2387-2007《工业设备化学清洗质量标准》腐蚀率≤6g/㎡·h的指标。

使用本品清洗后可以不需中和、漂洗、水冲洗,直接钝化处理,可在被清洗得设备表面形成保护膜。使用本品安全可靠,废液排放不需中和处理,对环境没有污染。

使用本品不仅省水、省电、省工、省时,而且节约、环保、高效、安全的清洗产品。

物理性能:外观为白色固体粉末,水易容、无沉淀;水溶后PH值6.0~6.5,本品无味、无腐蚀、不燃不爆,不含无机酸和有机酸,能有效清除设备中沉积的水垢和锈垢;碳钢轧制鳞片、铁锈螯合反应除去。

本品使用温度:常温或加热使用;

本品适用性:

适用于石油、化工生产装置在线清洗;

开车前化学清洗(脱脂、清洗除锈)。

适用于民用及食品行业的装置化学清洗;

适用于中央空调的清洗;

使用轧钢制品的清洗及模具除锈清洗;

各种水垢、锈垢以及各种材质设备、管道、器件的化学清洗除垢。

LPC-0513 中性清洗剂操作方法

清洗前,需要确定具体的清洗目标和过程参数。

根据需求确定工件清洗要求;根据工件锈蚀污垢及污垢厚度确定本品所需浓度和清洗时间。

常温清洗:将LPC-0513配制水溶液浓度为5~8%,清洗浸泡或循环时间24~48小时;

加热清洗: 将LPC-0513配制水溶液浓度为3~5%,加温50~90℃(50℃以上除垢效果更佳),清洗浸泡或循环需8~6小时;上述清洗具体时间按实际情况确定。

清洗后处理:用氮气吹干或清洗后直接调PH值为8加入钝化剂钝化;或铁离子浓度过高置换后用本品漂洗后调PH值钝化。

注意:

使用本品循环或浸泡清洗时:当除垢较厚时若一次清洗不彻底的设备,可按3~5%的浓度补加或重新配置LPC-0513清洗剂,再继续清洗,化学清洗时,在设备上部要开启排气孔充满即可。

塑料编制袋或纸袋包装:净重25kg/袋,室内保存,有效期二年《联系电话:13974961586》

ZL C-0513 PH Neutral Cleaning Agent ZHONGLAN Cleaning

Environment conservative and PH Neutral Cleaning Agent LPC-0513

This product is applied in all scale and rust from the petroleum and chemical equipment and industrial machining on the running process. This product has good cleaning effect and is reliable in safety, more safe, more environment protective, more economic, and more practical. Besides, it has earned National Award of technological Invention.

the rate of corrosion of carbon steel, stainless steel, yellow metal, copper and aluminum alloy is less than 0.3g/㎡·h according to the corrosion trial with this product,since the standard rate of corrosion of above-mentioned metal materials is ≤6g/㎡·h according to HG/T2387-2007,“The quality standard of chemical cleaning of industrial equipment”.

The protective film can be easily made on the surface of metal materials with this product and it is not necessary to neutralize and rinse with water before deactivation. It’s safe, non-poisonous, no pollution to the environment since the wasted water can be discharged directly without neutralized treatment after cleaning process.

The expense of water, power, man-power, time in the running process can be saved, And it is economic, environmental conservative, efficient, safe product for cleaning metal materials.

Physical Property : It appearance is white solid powder, and it is soluble in water,

Without precipitation, also the PH value of its water solvent is 6.0~6.5. It is Non-poisonous, tasteless, no corrosion, no combustion and explosion, it has no content of inorganic acid and organic acid , effectively not only cleaning scale and rust on the surface or equipment, but also removing carbon steel scale and rust by chelating reaction.

Temperature in application: it can be used under the normal temperature or heating circumstance.

Applicability:

Online clean for the petroleum and chemical devices;

The chemical cleaning when start-run (degreasing, rust cleaning);

Civilian and food service industry devices;

Central air-condition;

Rolled steel products and mould;

All scale, rust on the surface of all devices, pipes or chemical equipments.

Instruction of LPC-0513 PH neutral cleaning detergent

The clean- process parameters should be decided before clean-work start.

The cleanness requirement of the objects; according to the thickness of the rust or scale on the surface of objects, the concentration of the cleaning detergent solvent and clean-time should be decide。

Clean in normal temperature: the concentration of LPC-0513 water solvent should be in 5~8%(wt%), cleaning time is 24~48 hours.

Heating cleaning: the 3~5%(wt%)concentration of LPC-0513 in water is heated to 50-90℃, and cleaning time is 8-6 hours. The specific time is based on the actual situation.

After-treatment: After cleaning by water or nitrogen gas ,PH value of the solvent should be adjust to 8 before adding the deactivation detergent;

Notice:

When cleaning: 3~5% content ofLPC-0513 water solvent should be set up again if the effect of the original clean is not good because of the thickness of scale or rust. Make sure that the vessel should be full of the solvent by open the vent value when cleaning.

Plastic package or paper package: net weight 25kg/package, Indoor preservation, 2 years of period of validity.

Contact Tel: 13974961586

甲醇合成反应器不锈钢和碳钢器件中性清洗剂浸泡清洗后

The stainless and carton steel devices of methanol synthesis reactor after soaking and cleaning.

不锈钢、碳钢浸泡清洗前Stainless carbon steel before soaking and cleaning.

中性清洗剂

Neutral cleaning agent

蒸汽管道中性清洗剂清洗后 Steam pipe after neutral cleaning agent.

碳钢甲醇净化器储罐中性清洗剂清洗后The carbon steel methanol purifier storage tank after neutral cleaning agent.

碳钢蒸汽管道循环清洗后carbon steel steam pipe was circulated cleaned.

蒸汽管道清洗前 The steam pipe before the cleaning.

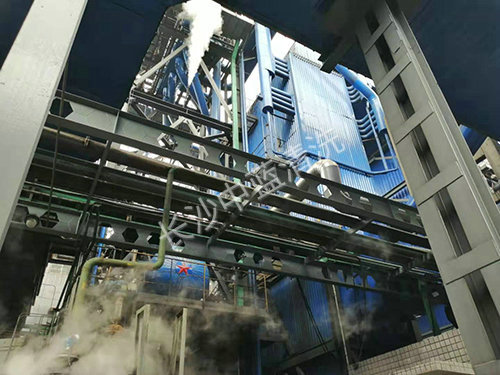

中性清洗剂锅炉清洗后

The cleaned boiler when using Neutral Cleaning Agent.

锅炉清洗后锅检所手孔割管检查

After boiler cleaning, the hand hole cut pipe inspection by inspection and supervision bureau of boilers

perature: the concentration of LPC-0513 water solvent should be in 5~8%(wt%), cleaning time is 24~48 hours.

Heating cleaning: the 3~5%(wt%)concentration of LPC-0513 in water is heated to 50-90℃, and cleaning time is 8-6 hours. The specific time is based on the actual situation.

After-treatment: After cleaning by water or nitrogen gas ,PH value of the solvent should be adjust to 8 before adding the deactivation detergent;

Notice:

When cleaning: 3~5% content ofLPC-0513 water solvent should be set up again if the effect of the original clean is not good because of the thickness of scale or rust. Make sure that the vessel should be full of the solvent by open the vent value when cleaning.

Plastic package or paper package: net weight 25kg/package, Indoor preservation, 2 years of period of validity.

Contact Tel: 13974961586

甲醇合成反应器不锈钢和碳钢器件中性清洗剂浸泡清洗后

The stainless and carton steel devices of methanol synthesis reactor after soaking and cleaning.

不锈钢、碳钢浸泡清洗前Stainless carbon steel before soaking and cleaning.

中性清洗剂

Neutral cleaning agent

蒸汽管道中性清洗剂清洗后 Steam pipe after neutral cleaning agent.

碳钢甲醇净化器储罐中性清洗剂清洗后The carbon steel methanol purifier storage tank after neutral cleaning agent.

碳钢蒸汽管道循环清洗后carbon steel steam pipe was circulated cleaned.

蒸汽管道清洗前 The steam pipe before the cleaning.

中性清洗剂锅炉清洗后

The cleaned boiler when using Neutral Cleaning Agent.

锅炉清洗后锅检所手孔割管检查

After boiler cleaning, the hand hole cut pipe inspection by inspection and supervision bureau of boilers

本品针对各类石油、化工装置及工业机加工时在生产过程中生成的水垢和锈垢,具有优良的清洗效果,使用安全可靠;比传统的清洗更安全、环保、经济和实用。

对碳钢、不锈钢、黄铜、紫铜和铝等材质的腐蚀率<0.3g/㎡·h以下, 对以上材质器件清洗过程中腐蚀远远低于HG/T2387-2007《工业设备化学清洗质量标准》腐蚀率≤6g/㎡·h的指标。

使用本品清洗后可以不需中和、漂洗、水冲洗,直接钝化处理,可在被清洗得设备表面形成保护膜。使用本品安全可靠,废液排放不需中和处理,对环境没有污染。

使用本品不仅省水、省电、省工、省时,而且节约、环保、高效、安全的清洗产品。

物理性能:外观为白色固体粉末,水易容、无沉淀;水溶后PH值6.0~6.5,本品无味、无腐蚀、不燃不爆,不含无机酸和有机酸,能有效清除设备中沉积的水垢和锈垢;碳钢轧制鳞片、铁锈螯合反应除去。

本品使用温度:常温或加热使用;

本品适用性:

适用于石油、化工生产装置在线清洗;

开车前化学清洗(脱脂、清洗除锈)。

适用于民用及食品行业的装置化学清洗;

适用于中央空调的清洗;

使用轧钢制品的清洗及模具除锈清洗;

各种水垢、锈垢以及各种材质设备、管道、器件的化学清洗除垢。

LPC-0513 中性清洗剂操作方法

清洗前,需要确定具体的清洗目标和过程参数。

根据需求确定工件清洗要求;根据工件锈蚀污垢及污垢厚度确定本品所需浓度和清洗时间。

常温清洗:将LPC-0513配制水溶液浓度为5~8%,清洗浸泡或循环时间24~48小时;

加热清洗: 将LPC-0513配制水溶液浓度为3~5%,加温50~90℃(50℃以上除垢效果更佳),清洗浸泡或循环需8~6小时;上述清洗具体时间按实际情况确定。

清洗后处理:用氮气吹干或清洗后直接调PH值为8加入钝化剂钝化;或铁离子浓度过高置换后用本品漂洗后调PH值钝化。

注意:

使用本品循环或浸泡清洗时:当除垢较厚时若一次清洗不彻底的设备,可按3~5%的浓度补加或重新配置LPC-0513清洗剂,再继续清洗,化学清洗时,在设备上部要开启排气孔充满即可。

塑料编制袋或纸袋包装:净重25kg/袋,室内保存,有效期二年《联系电话:13974961586》

ZL C-0513 PH Neutral Cleaning Agent ZHONGLAN Cleaning

Environment conservative and PH Neutral Cleaning Agent LPC-0513

This product is applied in all scale and rust from the petroleum and chemical equipment and industrial machining on the running process. This product has good cleaning effect and is reliable in safety, more safe, more environment protective, more economic, and more practical. Besides, it has earned National Award of technological Invention.

the rate of corrosion of carbon steel, stainless steel, yellow metal, copper and aluminum alloy is less than 0.3g/㎡·h according to the corrosion trial with this product,since the standard rate of corrosion of above-mentioned metal materials is ≤6g/㎡·h according to HG/T2387-2007,“The quality standard of chemical cleaning of industrial equipment”.

The protective film can be easily made on the surface of metal materials with this product and it is not necessary to neutralize and rinse with water before deactivation. It’s safe, non-poisonous, no pollution to the environment since the wasted water can be discharged directly without neutralized treatment after cleaning process.

The expense of water, power, man-power, time in the running process can be saved, And it is economic, environmental conservative, efficient, safe product for cleaning metal materials.

Physical Property : It appearance is white solid powder, and it is soluble in water,

Without precipitation, also the PH value of its water solvent is 6.0~6.5. It is Non-poisonous, tasteless, no corrosion, no combustion and explosion, it has no content of inorganic acid and organic acid , effectively not only cleaning scale and rust on the surface or equipment, but also removing carbon steel scale and rust by chelating reaction.

Temperature in application: it can be used under the normal temperature or heating circumstance.

Applicability:

Online clean for the petroleum and chemical devices;

The chemical cleaning when start-run (degreasing, rust cleaning);

Civilian and food service industry devices;

Central air-condition;

Rolled steel products and mould;

All scale, rust on the surface of all devices, pipes or chemical equipments.

Instruction of LPC-0513 PH neutral cleaning detergent

The clean- process parameters should be decided before clean-work start.

The cleanness requirement of the objects; according to the thickness of the rust or scale on the surface of objects, the concentration of the cleaning detergent solvent and clean-time should be decide。

Clean in normal temperature: the concentration of LPC-0513 water solvent should be in 5~8%(wt%), cleaning time is 24~48 hours.

Heating cleaning: the 3~5%(wt%)concentration of LPC-0513 in water is heated to 50-90℃, and cleaning time is 8-6 hours. The specific time is based on the actual situation.

After-treatment: After cleaning by water or nitrogen gas ,PH value of the solvent should be adjust to 8 before adding the deactivation detergent;

Notice:

When cleaning: 3~5% content ofLPC-0513 water solvent should be set up again if the effect of the original clean is not good because of the thickness of scale or rust. Make sure that the vessel should be full of the solvent by open the vent value when cleaning.

Plastic package or paper package: net weight 25kg/package, Indoor preservation, 2 years of period of validity.

Contact Tel: 13974961586

甲醇合成反应器不锈钢和碳钢器件中性清洗剂浸泡清洗后

The stainless and carton steel devices of methanol synthesis reactor after soaking and cleaning.

不锈钢、碳钢浸泡清洗前Stainless carbon steel before soaking and cleaning.

中性清洗剂

Neutral cleaning agent

蒸汽管道中性清洗剂清洗后 Steam pipe after neutral cleaning agent.

碳钢甲醇净化器储罐中性清洗剂清洗后The carbon steel methanol purifier storage tank after neutral cleaning agent.

碳钢蒸汽管道循环清洗后carbon steel steam pipe was circulated cleaned.

蒸汽管道清洗前 The steam pipe before the cleaning.

中性清洗剂锅炉清洗后

The cleaned boiler when using Neutral Cleaning Agent.

锅炉清洗后锅检所手孔割管检查

After boiler cleaning, the hand hole cut pipe inspection by inspection and supervision bureau of boilers

perature: the concentration of LPC-0513 water solvent should be in 5~8%(wt%), cleaning time is 24~48 hours.

Heating cleaning: the 3~5%(wt%)concentration of LPC-0513 in water is heated to 50-90℃, and cleaning time is 8-6 hours. The specific time is based on the actual situation.

After-treatment: After cleaning by water or nitrogen gas ,PH value of the solvent should be adjust to 8 before adding the deactivation detergent;

Notice:

When cleaning: 3~5% content ofLPC-0513 water solvent should be set up again if the effect of the original clean is not good because of the thickness of scale or rust. Make sure that the vessel should be full of the solvent by open the vent value when cleaning.

Plastic package or paper package: net weight 25kg/package, Indoor preservation, 2 years of period of validity.

Contact Tel: 13974961586

甲醇合成反应器不锈钢和碳钢器件中性清洗剂浸泡清洗后

The stainless and carton steel devices of methanol synthesis reactor after soaking and cleaning.

不锈钢、碳钢浸泡清洗前Stainless carbon steel before soaking and cleaning.

中性清洗剂

Neutral cleaning agent

蒸汽管道中性清洗剂清洗后 Steam pipe after neutral cleaning agent.

碳钢甲醇净化器储罐中性清洗剂清洗后The carbon steel methanol purifier storage tank after neutral cleaning agent.

碳钢蒸汽管道循环清洗后carbon steel steam pipe was circulated cleaned.

蒸汽管道清洗前 The steam pipe before the cleaning.

中性清洗剂锅炉清洗后

The cleaned boiler when using Neutral Cleaning Agent.

锅炉清洗后锅检所手孔割管检查

After boiler cleaning, the hand hole cut pipe inspection by inspection and supervision bureau of boilers